Lab2Market: JNCASR to set up India’s first CO2-to-methanol plant in Telangana

[ad_1]

BENGALURU: In a development that’s in line with India’s environmental goals and commitment to reduce carbon emission, Bengaluru’s Jawaharlal Nehru Centre for Advanced Scientific Research (JNCASR) is setting up the country’s first plant that can convert carbon dioxide (CO2) into methanol at a power plant in Telangana.

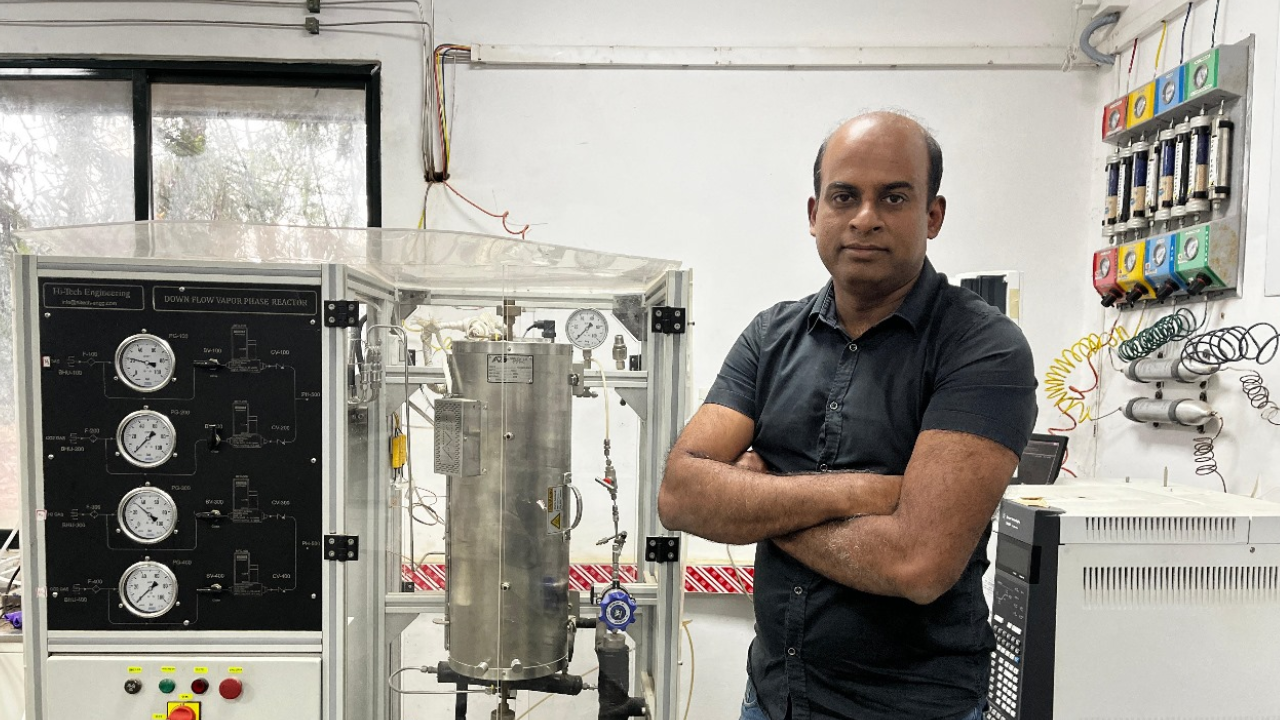

Prof Sebastian C Peter, faculty at JNCASR said his team first achieved the scientific breakthrough of converting CO2 into Methanol around 2020-21 after four years of development.Peter then incubated a startup — Breathe Applied Sciences — at JNCASR to demonstrate the technology’s economic viability.

“Once we had shown that this was economically viable, there was interest from multiple industries, and the Central Mine Planning & Design Institute Limited (CMPDI) with a recommendation from Coal India Limited is commissioning our plant, India’s first facility to convert CO2 to methanol, at the Singareni Collieries Company Limited (SCCL) power plant in Telangana’s Manchiryal district. We’ve completed the ground breaking ceremony on Saturday (Nov 25),” Peter told TOI. He added that the plant is expected to be commissioned in 2024.

The technology can help control environmental pollution by reducing CO2 and converts it to a useful chemical (methanol), which can be used in industries and commercial sectors. Pointing out that there’s a lot of demand for methanol globally, Peter said: “Currently, India imports almost 90% methanol from China, and its demand is expected to grow rapidly in the near future. The new plant will have the capacity to generate 300 litres of methanol every day.”

Lab-To-Market

Peter added that Breathe has translated fundamental research in catalytic chemistry to recycle anthropogenic carbon in the form CO2, into a technological solution to tackle the global problem of climate change and energy.

Pointing out that power production from combustion of fossil fuels releases CO2, Peter said while materials capable of cost-effective CO2 conversion into chemicals and fuels would help in stabilising atmospheric levels of greenhouse gas, there was no commercially viable process for the conversion of CO2 to useful chemicals and the existing state-of-the-art materials were expensive, which limit commercial implementation.

“This is the gap we addressed by creating our own propriety catalyst that helps us convert CO2 into methanol at an economically viable cost. Not only did we develop efficient catalysts for the conversion of CO2 to methanol and other chemicals, but we’ve also improved the process engineering to enhance production of chemicals and fuels from anthropogenic CO2. For instance, once the plant is ready, we will be producing a litre of methanol at Rs 25-35, while the current cost of methanol is in the range of Rs 35 and 45 a litre,” Peter said.

Prof Sebastian C Peter, faculty at JNCASR said his team first achieved the scientific breakthrough of converting CO2 into Methanol around 2020-21 after four years of development.Peter then incubated a startup — Breathe Applied Sciences — at JNCASR to demonstrate the technology’s economic viability.

“Once we had shown that this was economically viable, there was interest from multiple industries, and the Central Mine Planning & Design Institute Limited (CMPDI) with a recommendation from Coal India Limited is commissioning our plant, India’s first facility to convert CO2 to methanol, at the Singareni Collieries Company Limited (SCCL) power plant in Telangana’s Manchiryal district. We’ve completed the ground breaking ceremony on Saturday (Nov 25),” Peter told TOI. He added that the plant is expected to be commissioned in 2024.

The technology can help control environmental pollution by reducing CO2 and converts it to a useful chemical (methanol), which can be used in industries and commercial sectors. Pointing out that there’s a lot of demand for methanol globally, Peter said: “Currently, India imports almost 90% methanol from China, and its demand is expected to grow rapidly in the near future. The new plant will have the capacity to generate 300 litres of methanol every day.”

Lab-To-Market

Peter added that Breathe has translated fundamental research in catalytic chemistry to recycle anthropogenic carbon in the form CO2, into a technological solution to tackle the global problem of climate change and energy.

Pointing out that power production from combustion of fossil fuels releases CO2, Peter said while materials capable of cost-effective CO2 conversion into chemicals and fuels would help in stabilising atmospheric levels of greenhouse gas, there was no commercially viable process for the conversion of CO2 to useful chemicals and the existing state-of-the-art materials were expensive, which limit commercial implementation.

“This is the gap we addressed by creating our own propriety catalyst that helps us convert CO2 into methanol at an economically viable cost. Not only did we develop efficient catalysts for the conversion of CO2 to methanol and other chemicals, but we’ve also improved the process engineering to enhance production of chemicals and fuels from anthropogenic CO2. For instance, once the plant is ready, we will be producing a litre of methanol at Rs 25-35, while the current cost of methanol is in the range of Rs 35 and 45 a litre,” Peter said.

[ad_2]

Source link